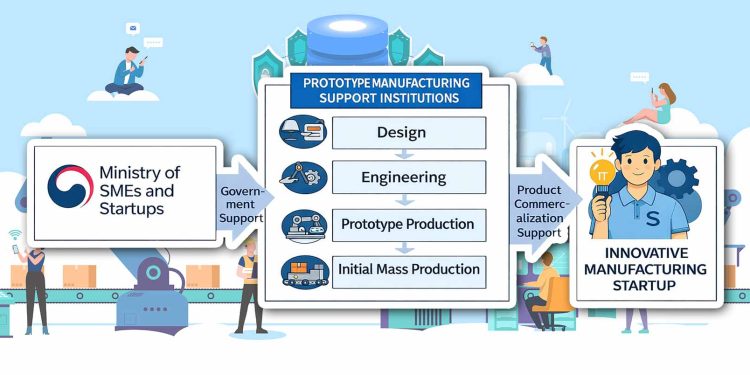

Korea’s Ministry of SMEs and Startups (MSS) has launched a new initiative that directly targets the most chronic weakness in its manufacturing startup ecosystem: the gap between prototype and production. The “All-in-One Pack Production” program consolidates every step of productization under a single management system, signaling a policy shift toward fixing the operational fractures that have long undermined startup survival.

MSS Introduces “All-in-One Pack Production” for Manufacturing Startups

The Ministry of SMEs and Startups announced on January 7, 2026, that it will implement a new “All-in-One Pack Production” program to support startups struggling with fragmented manufacturing processes.

The initiative was created in response to persistent structural issues in the manufacturing sector, where startups often depend on multiple vendors for different production stages—design, prototyping, tooling, and early mass production—causing information gaps, delays, and rising costs.

The MSS will appoint approximately six specialized manufacturing agencies capable of managing the entire product development cycle. Each agency will either carry out the production directly or connect startups with verified partners, ensuring a seamless flow between design and mass production.

A total of 80 innovative manufacturing startups will be selected to receive up to KRW 50 million (around USD 38,000) in productization support. The program enables startups to select customized assistance—such as design, prototyping, or pilot manufacturing—depending on their development phase and immediate needs.

Tackling the “Process Disconnection” in Manufacturing Startups

Korea’s startup ecosystem has long suffered from what policymakers and entrepreneurs describe as “process disconnection”—the tendency for manufacturing startups to lose momentum when moving from R&D to market-ready products.

Multiple studies and government hearings have pointed out that fragmented production workflows contribute to a high rate of startup failure, as costs multiply and product quality suffers during the transition to mass production.

This initiative marks the government’s first comprehensive attempt to address that structural flaw. It follows similar efforts under the Regulatory Sandbox Framework, where early manufacturing innovators such as Charzin demonstrated that pilot-stage support alone cannot guarantee long-term survival without scalable manufacturing continuity.

By integrating every phase of productization under one coordinating institution, the MSS aims to prevent startups from collapsing during the final and most capital-intensive stage of growth—mass production.

All-in-One Pack Production: “From Fragmentation to Continuity”

According to Cho Kyung-won, Director of Startup Policy at the Ministry of SMEs and Startups,

“The biggest challenge manufacturing startups face is the process discontinuity that occurs when each stage operates separately. Through the All-in-One Pack Production program, we will complete a system that connects design to early mass production so startups can overcome early product failures and achieve stable market entry.”

Industry observers have welcomed the initiative as a practical, long-overdue correction to Korea’s startup policy design. For years, founders have cited the absence of continuous, end-to-end support as the single biggest cause of failure in manufacturing-based entrepreneurship.

Korea’s Shift Toward Execution-Based Startup Policy

The All-in-One Pack program represents a structural evolution in how Korea approaches startup support—moving from project-based funding toward execution-based continuity.

By entrusting production oversight to specialized manufacturing institutions, the policy reflects a growing government realization that innovation without production scalability is unsustainable. The initiative also aligns with Korea’s broader 2026 startup strategy, which emphasizes industrial self-sufficiency, smart manufacturing, and venture-driven exports.

For global investors, this development signals that Korea is not just funding innovation but restructuring the mechanisms of scale-up success. Startups capable of bridging R&D with manufacturing execution will gain stronger access to public funding and private venture capital confidence.

At the same time, the program will test the government’s ability to manage complex public–private collaboration efficiently. As seen in previous initiatives such as the Deep Tech Challenge Project (DCP)—which allocates up to KRW 20 billion per consortium for R&D—the challenge now lies in operational accountability.

Building a System That Delivers, Not Just Promises

The All-in-One Pack initiative is more than another funding announcement—it is a statement about policy maturity. Korea’s manufacturing startups have shown creativity and technical competence but often lack structural continuity between idea and execution.

If successfully implemented, this program could become a blueprint for how governments worldwide integrate early-stage innovation with scalable manufacturing ecosystems. If not, it risks joining a list of well-intentioned policies that stalled at the point of delivery.

For now, Korea’s next phase of startup policy will be measured not by how much support is announced—but by how effectively its startups can cross the bridge from prototype to production without falling through the cracks again.

– Stay Ahead in Korea’s Startup Scene –

Get real-time insights, funding updates, and policy shifts shaping Korea’s innovation ecosystem.

➡️ Follow KoreaTechDesk on LinkedIn, X (Twitter), Threads, Bluesky, Telegram, Facebook, and WhatsApp Channel.