In a rapidly evolving aerospace industry, where the line between dreams and reality blurs, a group of extraordinary young researchers in South Korea is defying expectations and revolutionizing space exploration. Abyssal Aerospace, an emerging private aerospace research organization founded by ambitious high school and college students, is challenging norms and aiming to achieve what even experienced professionals find tough. With a passion for rockets and a shared desire to make their mark in the aerospace industry, these young researchers want to manufacture their rockets.

Abyssal Aerospace was established in 2017 by CEO Kang Joon-seo when he was just 14 years old and still in middle school. Recognized as a prodigious student, Kang had already demonstrated his exceptional talent in mathematics and physics, earning him the trust and respect of his peers. Lee Jae-jeong, the director of Abyssal Aerospace, is currently an undergraduate student majoring in aerospace engineering at Seoul National University

The organization has grown, incorporating more members from diverse backgrounds, from high school students to PhD holders. Although their paths to joining Abyssal Aerospace differ, they all share the same unwavering spirit and determination to “make a rocket themselves.” Their relentless pursuit of innovation has attracted attention and support from various quarters, including the online manufacturing platform CAPA, which plays a pivotal role in their ambitious endeavors.

CAPA’s Role in Empowering Abyssal Aerospace’s Ambitious Goals

CAPA, a frontrunner in facilitating outsourcing of manufacturing processes across various industries, has become an indispensable partner for Abyssal Aerospace. By connecting the organization with a vast network of manufacturing partners, CAPA enables them to procure essential parts needed for their rocket development projects. From requesting quotes to ordering and receiving finished products, Abyssal Aerospace leverages CAPA’s platform to streamline their manufacturing workflow, saving valuable time and resources.

While Abyssal Aerospace conducts most of its work online, it requires fieldwork for processing and procuring parts. This challenge is effectively addressed by CAPA’s online manufacturing platform. By utilizing CAPA’s services, Abyssal Aerospace can now complete the outsourcing of manufacturing entirely online, streamlining their operations and saving time from comparing quotes to ordering and receiving the finished products.

CAPA’s contribution to Abyssal Aerospace’s endeavors is exemplified by the adapters they recently obtained for the demonstration of their liquid output device. Through a simple process of requesting a quote from CAPA, Abyssal Aerospace was able to procure the necessary components, further solidifying CAPA’s role in the advancement of Korea’s aerospace industry. By leveraging CAPA’s platform, companies like Abyssal Aerospace can access a wide range of manufacturing capabilities and expertise, accelerating their prototyping and production processes while ensuring high-quality results.

Projects by Abyssal Aerospace

Abyssal Aerospace’s notable project was the ‘Hector Project,’ which spanned from 2017 to 2020. During this project, Abyssal Aerospace aimed to launch a solid propellant-based sonic projectile using artificial sugars. Choosing artificial saccharides as their propellant had practical advantages, such as affordability and ease of accessibility. By combining potassium nitrate and sorbitol, commonly found in products like Coke Zero, they created a propellant called ‘rocket candy’ and successfully launched a projectile using this propellant.

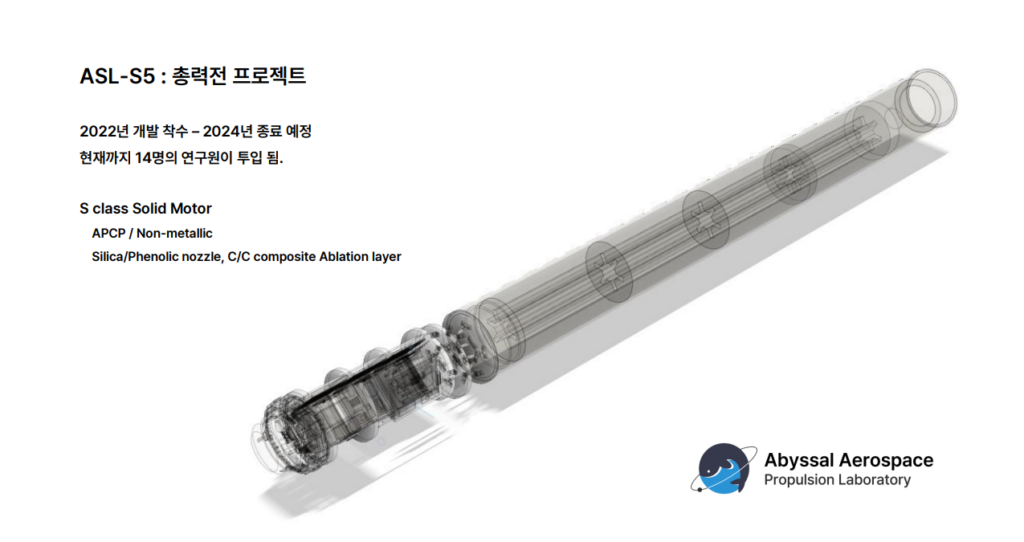

From 2020 to 2021, the organisation carried out a project to develop APCP high-performance solid propellants based on ammonium perchlorate. This propellant offers higher output and stability than the artificial sugar-based propellants but comes with the challenge of being expensive and difficult to obtain. Unfazed by these obstacles, the Abyssal Aerospace team created their own ammonium perchlorate and conducted combustion tests. Notably, APCP is recognized as the fuel used in solid boosters for rockets made by NASA.

As of 2023, Abyssal Aerospace is developing a liquid propellant engine that uses methane and oxygen and is working on a project to develop the necessary infrastructure for its operation. The transition from solid to liquid propellants demonstrates their commitment to pushing boundaries and exploring new frontiers in rocket technology.

The Abyssal Aerospace team recently managed to build and ignite a liquid propellant engine powered by methane and oxygen. It is currently in the technical validation phase. The Abyssal Aerospace team recently managed to build and ignite a liquid propellant engine powered by methane and oxygen

In the second half of this year, the organisation plans to build facilities for actual output tests and launch a projectile. Abyssal Aerospace aims to put a space launch vehicle equipped with their newly developed cryogenic methane-oxygen propellant into outer space at an altitude of 100 km or higher.

Director of Research at Abyssal Aerospace, Lee Jae-jeong, emphasized the organization’s ultimate goal: “We are doing everything under the goal of ‘making a launch vehicle that goes into space.'” Abyssal Aerospace’s remarkable achievements have sparked optimism for the future of Korea’s aerospace industry. Their unwavering spirit, paired with the support of platforms like CAPA, propels them closer to their grand dream of launching a space vehicle developed entirely in-house.

The source for this article is a Korean piece located at CAPA website. This version has been translated into English with additional revisions for clarity.

.Also Read,

- Korean space startup Innospace successfully launches suborbital test rocket HANBIT-TLV from Brazil

- Korean government pledges to nurture K-Space startups with 50 billion won ‘space fund’

- Korea’s first private manned space launch vehicle company Unastella attracts pre-A series investment

- Leading Korean & US accelerators sign deal to support startups in aerospace technology