When mobility industries chase lighter, stronger, and greener materials, breakthroughs rarely come from comfort zones. CMMC GmbH, founded by Dr. Marcel Graf—a pioneer in aluminium-matrix continuous casting—represents that rare fusion of scientific precision and industrial pragmatism.

The German company was then selected among 40 companies joining K-Startup Grand Challenge (KSGC) 2025 Phase 2, Korea’s flagship government-backed accelerator connecting global innovators with Asian markets.

In this interview, Dr. Graf shares how CMMC is redefining what “lightweight” means for the future of mobility and why Korea may be its next production base.

CMMC GmbH: Reinventing Lightweight Materials for a Heavy Industry

Q1. What motivated you to start this company, and what core problem were you trying to solve?

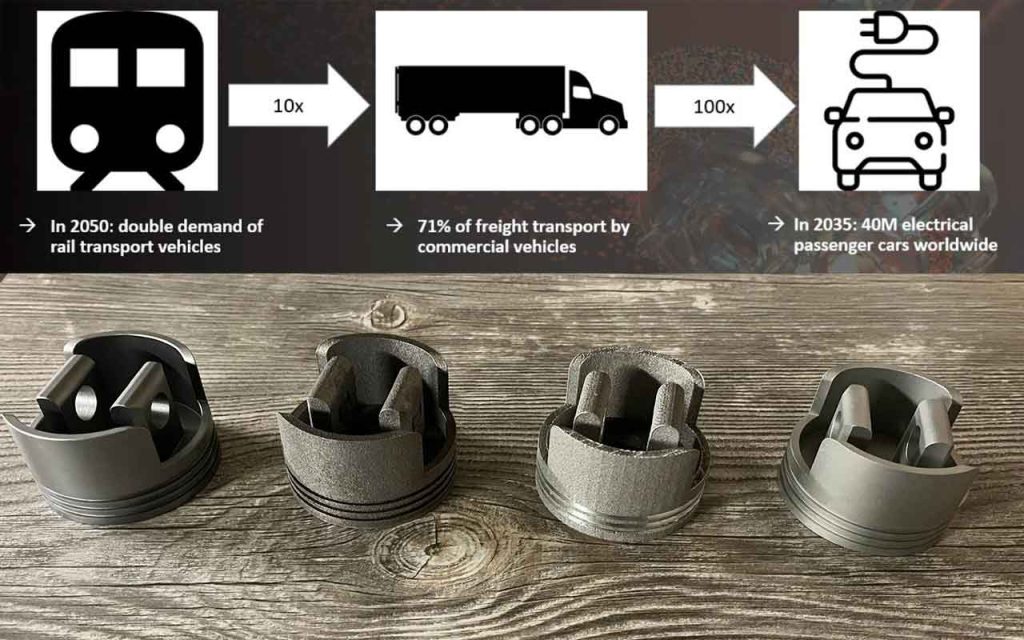

The mobility industry urgently needs large-scale, affordable lightweight solutions. Existing materials force a trade-off: aluminium offers lightness, ceramics offer durability, but combining the two has remained elusive. That limitation drives up cost, raises CO₂ emissions, and increases particulate matter.

We founded CMMC to break that barrier. Our Aluminium Matrix Composites (AMC) merge aluminium’s low weight with ceramics’ endurance in one sustainable material. By transforming AMC powder from a niche specialty into an industrial standard, we’re opening new markets with a genuine manufacturing breakthrough. Our “made-in-Germany” composite gives mobility sectors the performance they demand without environmental compromise.

Why Korea Became a Strategic Frontier for CMMC GmbH

Q2. What opportunity or unmet need did you identify in the Korean market, and what early signals convinced you that your solution could gain real traction here?

Korea’s engineering ecosystem excels in precision manufacturing but still faces a shortage of scalable lightweight materials. Aluminium remains popular for its low density and corrosion resistance, yet its mechanical strength trails that of steel or titanium. Ceramics, while strong and wear-resistant, are costly and hard to process.

Our Aluminium Matrix Composites close that gap, delivering lightness, durability, and cost efficiency—all essential for sustainable growth. Every kilogram that moves consumes energy; saving weight saves emissions.

We saw clear opportunity to bring our European AMC expertise to Korean OEMs and Tier 1–3 suppliers across diverse fields:

- Mobility: brake systems, pistons, clutches, gear wheels

- Aviation: planetary gears, dampers, drone components

- Defense: radar housings, ballistic panels, protective locks

- Mechanical engineering: spindles, bearings, machine bases

- Robotics: grippers, swivel joints

- Electronics: cooling plates

- Renewable energy: brake discs and bearing rings

Korea’s industries make it an ideal partner: rail manufacturing ranks among the world’s top 10 (USD 3 billion market, 2024); defense production will deliver 116 tanks between 2026–27; and by 2030, EV output is expected to reach 1.87 million BEVs—7 percent of global share.

Early traction has already begun. Testing is underway with LG, and strong discussions were held with Hites, Samsung, and Sensortec in July 2025, validating deep local interest.

For us, Korea isn’t just a customer market—it’s an innovation ally in sustainable material evolution.

Learning through Collaboration

Q3. During KSGC, were there any mentors, partners, or specific insights that significantly influenced your product or strategy?

KSGC introduced us to a global braking-system supplier whose technical feedback proved invaluable. Their insights opened new pathways for applying our Aluminium Matrix Composite materials far beyond automotive use. It was a reminder that collaboration, not competition, often accelerates innovation.

Validation through the Korean Ecosystem

Q4. After joining KSGC, what has been the most meaningful change for your company and what evidence supports this growth?

The conversations and evaluations we conducted in Korea confirmed that our direction is sound. Each discussion strengthened our conviction that we are aligned with the needs of advanced manufacturing sectors.

KSGC validated our approach, reinforced our B2B strategy, and gave us the confidence to deepen partnerships within Korea’s industrial network. The experience didn’t merely expand our contact list—it sharpened our long-term positioning in Asia’s mobility supply chain.

Building a Production Future in Korea

Q5. Looking ahead, what is the most important vision or long-term goal your company aims to achieve, and what steps are you taking to move toward it?

We plan to begin “zero-series” production of application-specific material solutions across mobility, defense, robotics, and aviation, then scale batch sizes as performance data and demand grow.

Our long-term vision is to establish a complete production line in South Korea, supplying SMEs and global players alike with locally developed Aluminium Matrix Composite materials. Producing in-country will shorten supply chains, reduce emissions, and position CMMC as a key partner in Korea’s quest for sustainable lightweight manufacturing.

Through the K-Startup Grand Challenge 2025, CMMC GmbH illustrates how deep-tech materials research can translate into tangible industrial sustainability—bridging Germany’s engineering precision with Korea’s manufacturing excellence.

“The experience and feedback gained through KSGC have reinforced our strategy and direction, validating our approach and providing confidence as we continue to expand and build partnerships in Korea.”

About This Series

This article is part of the “K-Startup Grand Challenge 2025 Interview Series,” featuring 40 global startups from Phase 2 of Korea’s leading accelerator program. The series highlights how international founders are scaling innovation through Korea’s startup ecosystem.

Read more stories from the K-Startup Grand Challenge 2025 Interview Series on KoreaTechDesk.

🤝 Looking to connect with verified Korean companies building globally?

Explore curated company profiles and request direct introductions through beSUCCESS Connect.

– Stay Ahead in Korea’s Startup Scene –

Get real-time insights, funding updates, and policy shifts shaping Korea’s innovation ecosystem.

➡️ Follow KoreaTechDesk on LinkedIn, X (Twitter), Threads, Bluesky, Telegram, Facebook, and WhatsApp Channel.