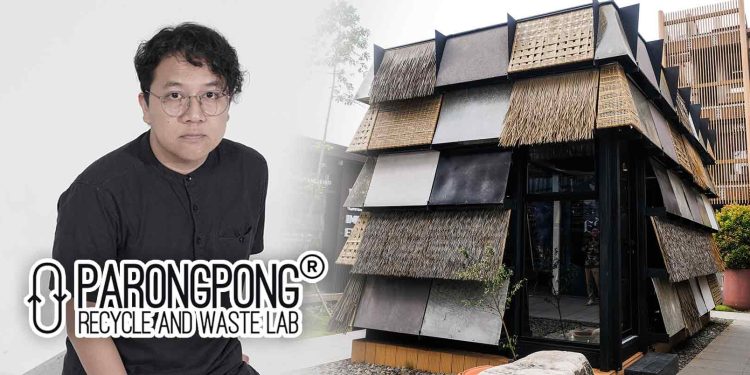

When most people see plastic debris tangled in fishing nets, they see pollution. Rendy Aditya, founder of Parongpong RAW Lab, sees potential — not only for sustainable materials but also for community-driven economies built from what others discard.

In an exclusive interview with KoreaTechDesk, Aditya explains how his Indonesian startup is turning ghost nets and mixed plastics into high-value materials, why Korea’s coastal ecosystems present a pivotal opportunity, and how the K-Startup Grand Challenge (KSGC) 2025 helped refine the roadmap toward Asia’s first decentralized circular material network.

“KSGC gave us strategic clarity, network, and confidence to execute a Korean expansion with real impact and long-term commercial viability.”

Turning Waste into Architecture with Parongpong RAW Lab

Q1. What motivated you to start this company, and what core problem were you trying to solve?

I founded Parongpong RAW Lab after recognizing a global gap in how waste is managed, especially in coastal and rural communities where discarded materials hold little or no value. Growing up in Indonesia, I saw fishing communities surrounded by ghost nets, low-value plastics, and other debris that harm marine ecosystems while offering no economic return. Meanwhile, global industries are demanding sustainable materials, yet existing recycling systems remain centralized, selective, and incapable of processing the waste that causes the greatest environmental damage.

As an architect and designer, I saw the potential hidden in these materials. What was missing was the right system and technology to unlock that value at scale. This inspired me to build Parongpong RAW Lab as both a material innovation lab and a circular economy enterprise with a core mission: to transform the world’s hardest-to-recycle waste into valuable, scalable materials that benefit both people and the planet.

Using our Prototech™ hydrothermal technology, we process dirty, mixed waste—particularly ghost nets—and convert it into high-quality, traceable materials such as Prototiles and Oriplas. This approach enables the creation of microfactories close to waste sources, empowers local communities, and provides industries with sustainable material alternatives.

My motivation remains deeply personal: to prove that circularity is not just a concept, but a practical system capable of uplifting communities, restoring environments, and shaping new sustainable economies worldwide.

Why Korea’s Coastlines Hold Global Potential for Parongpong RAW Lab

Q2. What opportunity or unmet need did you identify in the Korean market, and what early signals convinced you that your solution could gain real traction here?

In Korea, we identified a critical unmet need: a scalable, cost-efficient solution for processing **fishing gear waste—particularly ghost nets—**which remain one of the most persistent sources of marine pollution. While Korea has advanced recycling systems, similar to many other countries, the most problematic materials—mixed plastics, dirty nets, and ocean-bound waste—are still difficult to process using conventional methods.

We received strong early signals from the Korean market. Through discussions with local experts, port authorities, researchers, and KSGC mentors, we learned that Korea is actively investing in marine waste reduction, circular material development, and ESG-aligned manufacturing. Both government initiatives and corporate sustainability programs are setting ambitious targets to reduce ocean waste and accelerate the adoption of advanced recycling technologies.

Moreover, there was also a second, equally powerful signal that came from cultural trends. Korea’s rapid adoption of green building materials, sustainable retail interiors, and innovative public-space design aligns perfectly with our design-driven circular products. This combination of market readiness, policy momentum, and technical need confirmed that Korea is not just an opportunity—it is the ideal early gateway for scaling our technology across East Asia.

Learning to Scale Through Visibility

Q3. During KSGC, were there any mentors, partners, or specific insights that significantly influenced your product or strategy?

Yes—one key insight from KSGC significantly sharpened our strategy. Through discussions with Korean municipal advisors and sustainability mentors, we realized that the fastest path to market in Korea was not through large infrastructure projects, but through high-visibility, small-scale public installations that could demonstrate performance and build trust.

This insight completely shifted our approach. Instead of immediately focusing on full-scale microfactory deployment, we prioritized pilot installations in collaboration with designers, architects, and coastal communities. Mentors emphasized that Korean partners value proof of durability, design quality, and community impact before committing to larger-scale procurement.

We also received valuable input from local manufacturing and materials experts, who guided us in refining product specifications—color, texture, and form factors—to better align with Korean urban design preferences.

Together, these strategic and technical insights helped clarify our roadmap: start small, demonstrate visible impact, localize aesthetics, and scale through municipal and corporate partnerships.

Parongpong RAW Lab at KSGC 2025: Turning Clarity into Direction

Q4. After joining KSGC, what has been the most meaningful change for your company and what evidence supports this growth?

Since joining KSGC, the most meaningful change for Parongpong RAW Lab has been the strategic clarity and market direction gained for our expansion into Korea. Before entering the program, we had strong traction in Indonesia—processing ghost nets, mixed plastics, and industrial waste into high-value materials such as Prototiles and Oriplas. Through KSGC, we were able to translate this experience into a focused, Korea-specific roadmap.

One of the key developments was the validation of Korea as a high-potential market for circular materials derived from fishing gear waste. Through consultations with mentors and ecosystem partners, we confirmed a strong alignment between Korea’s marine-pollution priorities and our Prototech™ hydrothermal technology. This gave us confidence to begin preparation for our first Korean pilot project.

While we are still securing a successful local processing case for Korean ghost nets, KSGC enabled us to identify key coastal regions with the highest potential—Busan, Ulsan, and Jeju. On my next visit to Korea, I will meet prospective partners from port authorities, fisheries cooperatives, and sustainability-focused corporations to advance these plans.

As a direct outcome of KSGC, we are now preparing to secure our first LOI and MoU in 2026, targeting collaboration for a Korean microfactory and material demonstration project. This shift—moving from exploration to structured market-entry strategy—marks the strongest evidence of our growth. We now have the clarity, network, and confidence to execute a Korean expansion with real impact and long-term commercial viability.

Designing a Decentralized Circular Economy

Q5. Looking ahead, what is the most important vision or long-term goal your company aims to achieve, and what steps are you taking to move toward it?

Our long-term vision is to build Asia’s most impactful decentralized circular material network, where microfactories in coastal regions transform ghost nets, mixed plastics, and other abandoned materials into valuable, traceable products used by global industries.

We aim to prove that circularity can be both environmentally restorative and financially scalable, particularly in nations with large fishing industries and complex waste challenges.

In this vision, Korea plays a central role. If we can validate our model in one of the world’s most advanced economies, it will serve as a blueprint for scaling across Asia. Over the next two years, our goal is to establish Korea’s first Prototech™ microfactory pilot, process locally collected ghost nets into durable construction materials, and supply early adopters such as architecture firms, ESG-focused corporates, and public-sector partners.

To realize this, we are taking several key steps:

- Conducting Korean ghost-net material tests to optimize formulas.

- Engaging potential partners in Busan and Jeju for collection, sorting, and pilot deployment.

- Preparing technical documents and compliance materials for Korean certification.

- Building a network of early adopters eager to integrate circular materials into their products and infrastructure.

Ultimately, our goal goes beyond recycling waste. We seek to build a new circular economy model—one where communities, industries, and ecosystems thrive together through shared sustainability and innovation.

As the company successfully advanced through Phase 2 of K-Startup Grand Challenge 2025, Parongpong RAW Lab exemplifies how circular design can move beyond theory into scalable impact.

By merging Indonesia’s field-tested innovation with Korea’s advanced infrastructure, the company is charting a path where ocean waste becomes the foundation of architecture, art, and sustainable urban design.

About This Series

This article is part of the “K-Startup Grand Challenge 2025 Interview Series,” featuring 40 global startups from Phase 2 of Korea’s leading accelerator program. The series highlights how international founders are scaling innovation through Korea’s startup ecosystem.

Read more stories from the K-Startup Grand Challenge 2025 Interview Series on KoreaTechDesk.

– Stay Ahead in Korea’s Startup Scene –

Get real-time insights, funding updates, and policy shifts shaping Korea’s innovation ecosystem.

➡️ Follow KoreaTechDesk on LinkedIn, X (Twitter), Threads, Bluesky, Telegram, Facebook, and WhatsApp Channel.