The hamburger is a familiar food to us all. At first glance, it seems easy to cook. The essence of the taste of a hamburger lies in the finely minced ‘patty.’ However, when you put yourself in the position of the person cooking the patty, you may discover unexpected ‘pain points.’

Hamburger patties are tricky – undercooking poses risks, and overcooking results in tasteless patties. The key is to cook the patties evenly for a set time on the grill. If you’re grilling one or two at home, it’s no problem. But what if you’re a hamburger joint cooking dozens to hundreds of patties a day? Standing guard in front of the grill amidst smoke and heat becomes laborious.

While there are numerous hamburger joints, finding one that consistently cooks delicious burgers takes work. In reality, cooking patties is not a task that requires extraordinary skills. It’s a mechanical and repetitive process – wait for a specific time, flip the patty, wait again, and it’s done. What if a machine or a robot could do this job?

The startup Aniai, a CAPA customer, has introduced a ‘robot’ to handle hamburger cooking. Aniai aims to reduce the need for employees while maintaining the taste and quality of hamburgers. Furthermore, by introducing robots, they seek to address the labor shortage issue in the food service industry. Aniai has partnered with CAPA to develop its robot.

Restaurant as a Small Factory, Solving ‘Labour Shortages’

Aniai is a startup founded by five co-founders, including CEO Hwang Geon-pil, in July 2020. CEO Hwang was a researcher at KAIST, developing advanced artificial intelligence (AI) recognition systems for smart factories. During this time, he realized that a restaurant is a small factory producing food according to recipes.

While operating a restaurant, he identified one of the most significant challenges: labor shortage. Considering the ease of quantifying the cooking process, especially for burgers, among various foods, and its potential to help address the labor shortage, burgers became the ‘testbed.’

Leveraging rapid execution capabilities, within just a year and a half of its founding, Aniai successfully launched and commercialized the ‘Alpha Kitchen Grill,’ a robot capable of automatically cooking hamburger patties, and the ‘Alpha Kitchen Sauce,’ which automatically distributes sauces. Currently, they have completed the development of the ‘Alpha Kitchen (αKitchen),’ a robotic kitchen system that can fully automate the production of burgers. It is set to be released next year.

Optimal Cooking Robot Designed by Robotics Experts

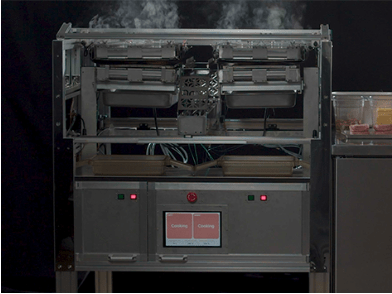

The ‘Alpha Kitchen Grill,’ which performs the entire process of cooking hamburger patties, is currently in use at the ‘Crycheeseburger Sangam branch. Human intervention involves simply placing the hamburger patty on the grill. Once the patty is on the grill, the robot presses it once. After a certain amount of time, it flips the patty, presses it again, and, when the cooking is complete, not only removes the patty but also cleans the grill.

If you were expecting a robot chef resembling a human, you might be somewhat disappointed. The Alpha Kitchen Grill (refer to the photo below) is not the typical humanoid robot that one might imagine when thinking about robots cooking burgers.

Aniai’s robot development team consists of experts with extensive experience in robot design, including participation in the development of humanoid robots like ‘Hubo’ at KAIST. They have designed the robot in an optimized form for cooking burgers from the perspective of robotics experts.

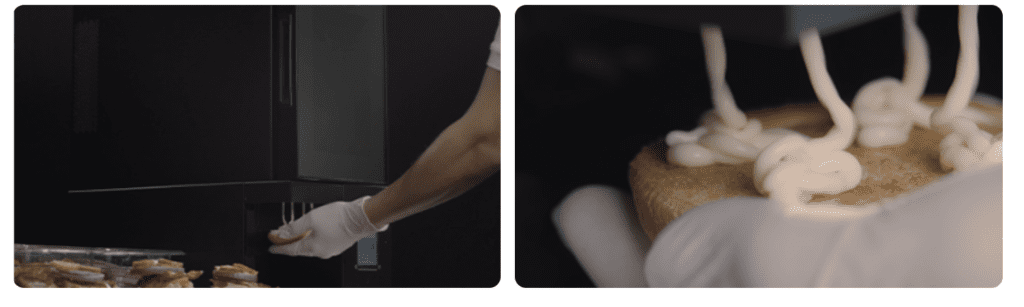

Optimized for producing and distributing sauces according to precise recipes to achieve a consistent flavor, the ‘Alpha Kitchen Sauce’ (refer to the photo below) is currently in use at ‘Lotteria’ stores. By utilizing the sauce robot, kitchen staff can freely use both hands in the kitchen, and the robot can simultaneously dispense various types of sauces in measured quantities.

Recognized for its technical expertise in the US

Aniai is gearing up for expansion into the birthplace of burgers, the United States. Particularly noteworthy is its selection from the AWS Robotics Startup Accelerator, a program supporting promising startups worldwide in the field of robotics, with only 17 companies chosen globally. This acknowledgment signifies that Aniai’s technological prowess holds potential on the international stage, bringing forth a multitude of benefits.

Benefits include:

- Customized robotics solutions provided by AWS experts.

- Business mentoring from market professionals.

- Sharing of Amazon’s innovation methods.

- Company promotion through Amazon’s social media, blogs, etc.

- Opportunities to meet with innovators and entrepreneurs in the robotics industry.

In addition, Aniai has the chance to participate in an educational program offered by MassRobotics, the world’s largest non-profit robotics technology innovation center. This opportunity allows EniAi to learn about the specific requirements for its robots in the US market and understand the strategies needed for success. Currently, the collaboration between AWS and Aniai is in the process of identifying key areas for cooperation.

Recognized in Korea by MS, SK, NextRise, etc.

Aniai’s exceptional technical capabilities have already been validated in the domestic market through recognition from major corporations such as Microsoft, SK, and NextRise.

In 2021, Aniai was selected as a finalist in the Microsoft Incubator Program, and, it was chosen as a collaborative partner for the SKT ESG Korea 2022 program. The focus on kitchen automation robots aligns with the recent emphasis on ESG (Environmental, Social, Governance) aspects.

Moreover, Aniai was selected as a finalist in the Global Business Expansion Contest at NextRise 2022. This recognition has facilitated activities such as Investor Relations presentations in front of US investors, meetings and networking with Silicon Valley investors, and support for expert education in legal, tax, and HR aspects for the purpose of entering the US market.

Set to conquer the vast $10 trillion US market

Aniai sources various components used in the manufacturing of Alpha Kitchen through CAPA. Among these, parts produced using CNC or machining centers are exclusively handled through CAPA. In the initial stages, Aniai conducted numerous transactions with CAPA partner’ TierOne,’ and currently, it actively engages with ‘Top Engineering.’

As Aniai gears up for full-scale production both domestically and internationally, collaboration with manufacturing partners is expected to become even more critical. Importantly, the company plans to continue producing its products in Korea, even as it ventures into the US market.

Products like the specialized ‘Alpha Kitchen Grill’ for cooking hamburger patties, which can be consistently produced in the same form, are efficiently shipped from Korea to the US. This approach is deemed effective for a variety of reasons. For fully automated devices like ‘AlphaKitchen,’ which need to be customized according to the situation in each kitchen, the plan is to produce sub-module components in Korea and carry out final assembly in the US. The US hamburger market associated with the robot kitchen is estimated to be around 10 trillion won annually.

Aniai, which has been winning awards in various domestic and international competitions, is swiftly preparing for entry into the US market. CAPA visited Aniai’s lab and conducted an interview with CTO Jiminsoo and Team Leader Yeoseunggyun.

Q. How was Aniai established?

Hwang Geon-pil, our CEO, was originally developing advanced artificial intelligence systems for application in smart factories at KAIST. During this time, he came to think of a restaurant as essentially a ‘small factory’ producing food according to a recipe. Particularly with the current difficulty in hiring staff for running restaurants, resolving the ‘labor shortage’ in the restaurant industry using robots became a decision in starting this venture.

Aniai has a total of five co-founders, including CEO Hwang Geon-pil. All of them have engineering backgrounds, specializing in robotics and artificial intelligence, and graduated from KAIST and Seoul National University. They came together under a mission to ‘digitally transform kitchens (DX), ensuring hygiene, a safe working environment, and solving labor shortages.’

Q. Why did you prioritize ‘hamburgers’ among various foods?

For Korean dishes with complex recipes, it’s not easy to quantify and automate the cooking process. In contrast, hamburgers have a relatively simple cooking process, making them suitable as the first mission to be solved by robots. Starting with burgers, we plan to gradually expand the application scope. The ultimate goal is to automate all kitchens.

Q. Please describe the currently commercialized products.

We have ‘Alpha Kitchen Grill,’ a robot that automates the process of grilling burger patties, and ‘Alpha Kitchen Sauce,’ which accurately dispenses sauce. Both products are designed based on AI technology and sensing/control technology.

They can automatically produce food according to orders, to some extent replacing kitchen staff. The advantage is that robots can handle risky and strenuous tasks during the food production process. Not only can they efficiently repeat simple actions, but they can also work tirelessly 24 hours a day, contributing significantly to increased sales.

Q. Many burger joints tend to overcook patties; how does Robo Kitchen address this issue?

Currently, many restaurants are dealing with the ‘burger disease’ by ‘overcooking’ in busy kitchens, compromising the taste and quality of burgers for the sake of hygiene. In such a situation, Alpha Kitchen Grill perfectly maintains the appropriate temperature for the patties, addressing both taste and hygiene.

Q. Is it that difficult for a robot to grill patties?

Yes, it is. First, lifting the patty onto the grill is not easy for the robot, and it also needs to clean the grill if it wants to continue cooking. This is why even competitors have given up on it. Our team includes members who have designed many robots like ‘Hubo (a humanoid robot developed at KAIST),’ so from the beginning, we thought that we couldn’t solve this problem with the traditional approach. The reason why the Alpha Kitchen Grill we developed doesn’t look like the typical robot is precisely because of this.

Q. Specifically, how does the patty cooking process work?

In the basic process, after placing the patty on the grill, the robot presses it once. The initial task of putting the patty on the grill is still done by a person. After a certain amount of time, the patty is flipped, and it is pressed again. Similarly, after a certain amount of time, the patty is lifted and moved, and then the grill is cleaned. The most challenging and crucial part of a kitchen in a burger restaurant is the patty grilling process.

Typically, ‘veteran’ employees with more than six months of experience end up handling this task, and many cases involve them quitting due to the difficulty and strain. This is also why we decided to focus on the ‘patty’ when creating a burger robot. Fully automating the entire process of making burgers takes time and is challenging from a business perspective. We aimed to address the most pressing issue right away.

Q. Are there any competitors producing similar products?

In Korea, there don’t seem to be any (in the field of burger cooking). Internationally, there are two companies, Miso Robotics and Creator. Miso Robotics is a B2B specialized company, while Creator operates a burger restaurant using a robot they developed. Miso Robotics, like us, started developing a robot for grilling patties but eventually gave up and now only cooks french fries.

Most parts are procured from CAPA. “Let’s go together” in the future

Q. How did you source the components for the robot?

We currently source most of the various processed parts through CAPA. Especially, parts that require CNC machining or machining center work are all done through CAPA. In the early days, we traded a lot with a company called ‘Tier One,’ one of our CAPA partner companies, and lately, we’ve been working a lot with ‘Top Engineering.’ Since our product is directly related to ‘hygiene,’ the factory environment is crucial, and we visit actual factories to check these aspects. In the future, for newly developed parts, we plan to continue sourcing through CAPA.

Q. If you enter the US market, where do you plan to manufacture for mass production?

We are still in the decision-making stage, but producing in Korea, assembling, and then shipping to the US seems much more efficient in many ways. However, for devices like ‘Alpha Kitchen’ that require full automation and need to be installed according to the environment of each store, we might produce sub-module units in Korea and perform final assembly in the US.

Q. What is your business model?

We are considering the ‘subscription’ model, where we rent out robots and receive monthly fees, as the basic model. We are also thinking about various models that mix subscription and sales. Even if we sell, we are considering how to address issues such as product after-sales service or replacement of consumables. We plan to explore the feasibility of various approaches, including making it easy to manage stores using robots.

Q. Are there any US burger brands that you are prioritizing for contracts?

The US burger market does not have a structure where ‘Big 3’ dominates the market as in Korea. Various brands are active on a state-by-state basis. Therefore, rather than specifically targeting one or two places, we are in contact with various companies. It can be thought that we have exchanged conversations with almost all well-known US burger franchise companies in Korea.

Q. Besides technological prowess, what is another reason investors are paying attention to Aniai?

We heard it’s because of our excellent team composition and the size of the market. Looking at our team composition, it seems like the future is well laid out. However, the biggest factor is the size of the market. Just targeting the burger cooking market in the US has an annual scale of over 10 trillion won. Even if we only take 10%, it is 1 trillion won, which can be said to be an immensely large market.

Q. Are you relocating the headquarters to the United States?

You can see it as a change in the governance structure. The US corporation becomes the headquarters, and the Korean corporation becomes a subsidiary. In other words, we are not moving the headquarters to the US, but planning to move marketing and operation to the US, while continuing development and production in Korea. The transition to the US corporation is expected to be finalized within a year.

Aniai is preparing to unveil its products through the ‘NRA Show,’ also known as the ‘CES (Consumer Electronics Show)’ of the restaurant industry, before officially entering the US market next year. It will be a debut stage targeting the US restaurant industry. Aniai aims to solve persistent problems in the restaurant industry through robots and ventures into the birthplace of burgers, the United States. CAPA, will continue to work together to help Aniai thrive with the best manufacturing partners.

Also Read,

- Building Trust through Communication: Success Story of 3D Printing Partner ‘iContact’ on CAPA Platform

- UMTR Teams up with CAPA to Pioneer Localization of Biomembranes & Shape the Future of the Bio-Industry

- ZEEZIK Addresses LP Infrastructure Gap with Partnership with CAPA and Attracts MZ Generation

- Online Manufacturing Platform CAPA Partners Thrive at NextRise 2023, Showcasing the Future of Manufacturing

- Fuelling the Future: Young Korean innovators propel Rocket manufacturing with online support from CAPA

Keep tab on latest news in the Korean startup ecosystem & follow us on LinkedIN, Facebook, and Twitter for more exciting updates and insights.