As Korea deepens its national AI Transformation (AX) strategy, a growing number of small and medium-sized manufacturers are calling for stronger policy support. Recent survey findings reveal that many SMEs view AI adoption as essential to their survival, but face barriers in funding and technical talent — signaling an urgent need for inclusive industrial innovation policies.

SMEs Call for Action as AI Becomes Core to Manufacturing

Nearly half of Korea’s smart-factory SMEs now believe that adopting artificial intelligence (AI) in their production processes is essential for competitiveness, according to a survey by the Korea Federation of SMEs (KBIZ) involving 502 manufacturers that participated in the Win-Win Smart Factory Program over the past five years.

The study, conducted among 502 companies that participated in the Win-Win Smart Factory Program over the past five years, found that 47.4% of respondents considered AI introduction “necessary” or “very necessary,” while 78.5% agreed when moderate responses were included.

Results showed that demand was particularly high among firms with more advanced smart-factory systems — rising from 38.8% at the basic level to 58.4% at the advanced stage — indicating that as companies progress in digitalization, they develop a stronger awareness of AI’s role in improving efficiency, precision, and predictive control.

Korea AI Transformation (AX): Needs and Bottlenecks

Survey participants identified quality control (33.9%), production optimization (32.3%), and process automation (31.9%) as the top areas requiring AI integration. These reflect where small manufacturers see the clearest potential to raise productivity and product reliability.

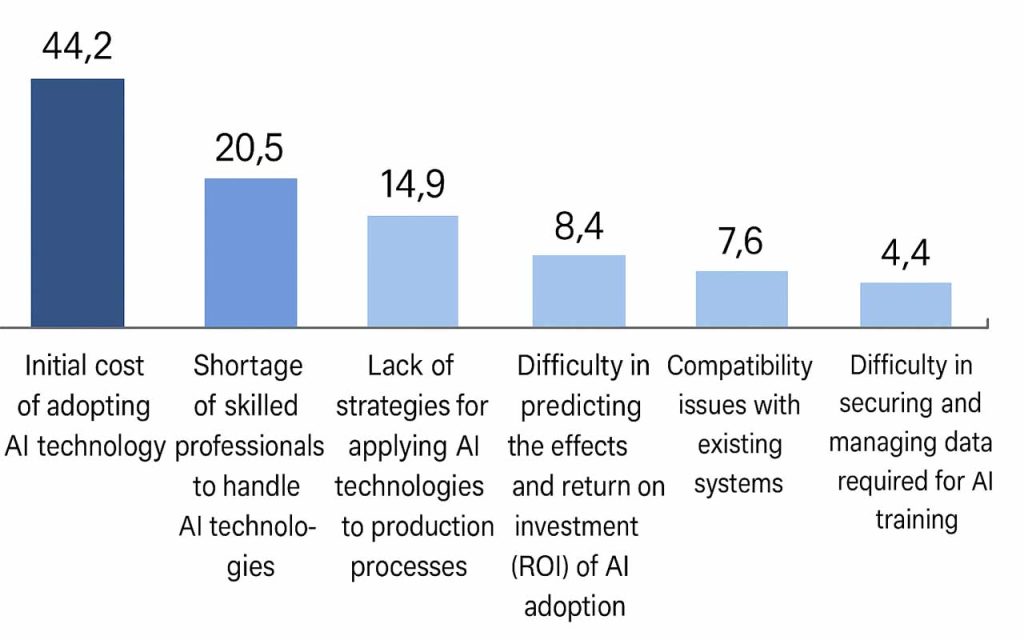

Yet the study also underscores persistent challenges. The initial cost burden (44.2%) and shortage of specialized personnel (20.5%) remain the top obstacles. Most companies said they could only invest less than KRW 100 million (USD ~70,000) in AI system upgrades, underscoring the financial strain on SMEs attempting to modernize.

Direct Funding and Skilled Workforce in Demand for Effective AI Transformation

Despite these constraints, 54.6% of respondents said they would actively participate if the government launches a new AI-based smart-factory support program — such as the proposed ‘AI Factory (AI팩토리)’ initiative currently under consideration by the Ministry of SMEs and Startups (MSS).

When asked what kind of assistance they need most, 72.3% cited direct financial support, followed by AI consulting and technical guidance (21.9%). This indicates that SMEs are not only seeking subsidies but also structured mentoring and skill-building programs to help them deploy AI efficiently.

MSS’s broader AI Transformation (AX) policy, already expanding through inter-ministerial cooperation with the Ministry of Trade, Industry and Energy (MOTIE) and the Ministry of Science and ICT (MSIT), is designed to address precisely these issues — linking funding, education, and infrastructure to accelerate digital autonomy in manufacturing.

Smart Factories in Practice: Gains and Gaps

Beyond AI adoption intent, the survey also examined how smart factories are currently performing and where operational gaps remain.

Among respondents, 77.1% said they are already benefiting from their smart-factory setups. Reported gains include productivity growth (42%), improved safety and work environments (36.1%), and better inventory and supply-chain management (25.5%).

However, gaps persist. Companies cited a shortage of skilled operators (43.8%) and high maintenance costs (25.9%) as continuing pain points. Data utilization also remains uneven — while 64.5% collect production data, only 58.3% actively analyze it, mainly due to lack of expertise or outdated equipment.

Aligning AI Transformation (AX) Policy with SME Reality

The findings provide crucial insight into Korea’s ongoing industrial digitalization. They suggest that while the government’s AX strategy and rising AI budgets are reshaping the national innovation agenda, execution at the SME level still hinges on two enablers — accessible funding and workforce development.

As Yang Chan-hoe, head of KBIZ’s Innovation Growth Division, emphasized, Korea must maintain a two-track policy: one for advanced manufacturers ready to scale AI adoption, and another for SMEs still at the basic digital-transformation stage.

This dual approach ensures that Korea’s AI transformation remains inclusive — fostering both global competitiveness and domestic resilience.

A Turning Point for Korea’s Manufacturing Industry

Korea’s manufacturing sector is approaching a decisive turning point. The government’s AI transformation policy offers a framework for industrial evolution, but its success will depend on bridging the financial and talent gaps that small manufacturers face.

That is why strengthening public-private collaboration in funding, training, and data utilization could position Korea’s SMEs at the center of Asia’s next wave of intelligent manufacturing.

🤝 Looking to connect with verified Korean companies building globally?

Explore curated company profiles and request direct introductions through beSUCCESS Connect.

– Stay Ahead in Korea’s Startup Scene –

Get real-time insights, funding updates, and policy shifts shaping Korea’s innovation ecosystem.

➡️ Follow KoreaTechDesk on LinkedIn, X (Twitter), Threads, Bluesky, Telegram, Facebook, and WhatsApp Channel.