Everyone must have used a self-diagnosis kit at least once when they felt symptoms of suspected COVID-19. The self-diagnosis kit is the principle of mixing reagents with bodily fluids and then dropping them on paper to determine whether you are infected with Coronavirus. Two red lines on the paper signal the possibility of a virus in the body.

The official name of the material that composes this paper is ‘Membrane.’ The self-diagnosis kit’s membrane is a biomembrane with coronavirus antibodies and helps antibodies and antigens (viruses) meet.

Due to the recent growth of the bio-industry and the aftermath of the pandemic, the demand for membrane filters is steadily increasing. In addition, membrane filters are used in water treatment fields to purify water and in various research fields such as laboratories. The problem is that the domestic supply of membranes is concentrated in some foreign companies. Due to the high market price due to the oligopoly, and the delivery period extended because it is imported from overseas, it isn’t easy to purchase quickly.

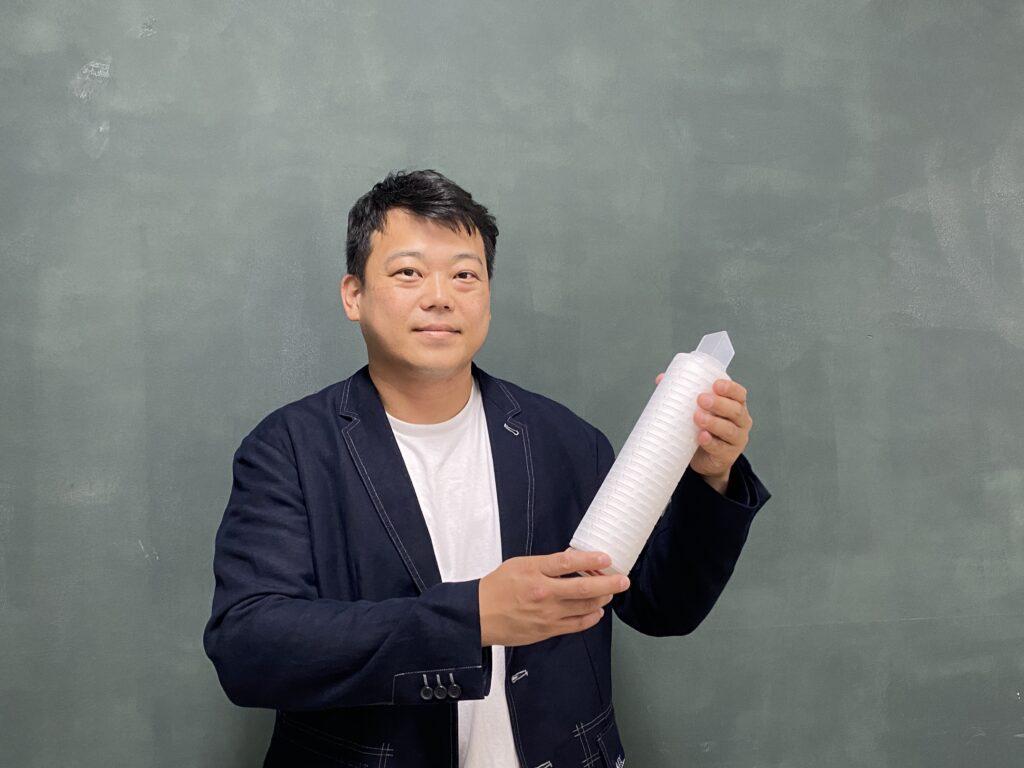

A Korean startup, ‘UMTR,‘ a customer of CAPA, an online manufacturing platform, is working hard to localize these membrane filters. UMTR is looking for a manufacturer on CAPA to make the parts needed to produce domestic membrane products. CAPA met CEO Park Seong-ryul at the UMTR office in Suwon, Gyeonggi-do.

The development of domestic membranes has sprouted

‘UMTR’ stands for ‘United Membrane Technology and Research’ and works with the mission of researching and developing membranes. The Korean name of the company ‘Umtle’ was conceived from the pronunciation of ‘UMTR’ and the verb’ Umtda,’ which means ‘to sprout a new sprout,’ another meaning of ‘starting up’ or ‘new luck or thinking.’ It is connected with the CEO Park Seong-ryul’s entrepreneurship process during COVID-19.

CEO Park Seong-ryul studied membrane technology at Lotte Chemical after completing graduate school. Afterward, he moved to the Korea Evaluation Institute of Industrial Technology, where he was in charge of the bio sector evaluation and watched related industries’ evolution. At the time, the biopharmaceutical and in vitro diagnostic device industries emerged as the main focus, and membranes were used as key components. However, companies that needed membranes depended on imports 100% and suffered from high prices and long delivery times from overseas suppliers.

CEO Park started a business to solve these difficulties and participated in the Korea Evaluation Institute of Industrial Technology’s in-house startup support program. Membrane filter development is a high-risk undertaking requiring a high degree of skill and expertise and an upfront capital investment. Nevertheless, CEO Park worked on operating UMTR with the startup support program.

Mission to help humanity is driving force for UMTR

UMTR’s representative products are bottle-top and centrifugal filters for bacteria removal and NC membranes for in vitro diagnostics. Filter products for removing germs are being developed to get wet faster and be filtered more quickly by adding hydrophilicity to the initially used membrane material. In addition, a large amount of contaminated water is generated when the filter is manufactured, and UMTR minimizes contamination by using materials with very low toxicity.

Seeking Partner on CAPA to grow together

CEO Park Seong-ryul considers eco-friendly factors as crucial as product quality. Solvents, gloves, etc., usually used in product research, are mostly disposable consumables and classified as non-recyclable and incinerated waste. CEO Park said he felt a sense of debt for this since his graduate school days. “It is a study to do something beneficial to the world, but when I saw the resources wasted in this process, I felt skeptical about whether it was right to do something beneficial,” he said

This is why CEO Park started the business and the reason for the existence of Umtle. If membrane production is localized, the growth of the bio-industry will be further accelerated. Umtle is making membrane products and, at the same time, creating an opportunity for humanity and the world to take a step forward.

UMTR’s goal for the special listing on CAPA is to meet a partner who will grow together. There is an assignment that UMTR has yet to solve. It is the filter mold. CEO Park Sung-ryul wants to purchase and use ready-made industrial cartridge filters already used in many fields, such as water treatment. However, it is difficult to find a manufacturer that handles the mold, and manufacturers with cartridge molds do not readily cooperate, expressing their disapproval.

CEO Park is confident that if he can reduce mold production costs, he can supply better membrane products. The purpose of using CAPA is to meet manufacturers who will achieve the development of humanity together. CEO Park is looking forward to meeting a manufacturer with the technology to automate membrane filter production and, above all, a manufacturer with a challenging spirit.

UMTR aims for a sales target of 10 billion won in 2025 and a special listing in the following year, 2026. “After listing, we plan to set up large-scale mass production facilities to look beyond membrane localization to export,” Park shared. The following is a Q&A with CEO Park Seong-ryul regarding the startup and the industry.

Q. Why is the localization of biomembranes necessary?

Until now, Korea has traditionally been in the assembly industry (importing raw materials and exporting processed products). However, parts and equipment processing raw materials have depended on the United States, Japan, and Germany. In the past, when free trade was active, such an industrial structure was not a big problem, but now, securing strategic materials has become a little tricky. The biopharmaceutical and in vitro diagnostic device industry is no different. I founded UMTR with the thought of making it more accessible.

Q. Who are the current clients of UMTR?

I would like to supply our products to Celltrion and Samsung Biologics. I have been working with Celltrion through the Shinhan Square Bridge program and getting help in product development for over two years. I tested the bottle top filter product directly based on the culture medium produced by Celltrion. Samsung Biologics commissioned the filter development this year, and we are working on it.

Q. How did COVID-19 affect your startup process?

People often say, ‘Choose and focus,’ but I developed multiple products simultaneously. The original plan was centered on biopharmaceuticals, but due to the outbreak of COVID-19, the direction changed to diagnostic kits. However, priorities have changed, but research on bottle-top and centrifugal filters has continued. So, when the endemic approached and the demand for bacteria removal filters increased compared to the diagnostic kit market, I was able to respond by adjusting my priorities again.

Q. What is the hardest thing about being a startup?

It takes a lot of work to launch as a startup.It’s difficult because it’s the first time for everything and an unfamiliar field; it is difficult to find investors and people in charge of research projects. Still, many people who have encountered our development of domestic membranes appreciate and say things such as ‘doing what is essential for society’ and ‘I hope it becomes the foundation of the industry by succeeding.’ I hope that institutions and governments will show more interest and support.

Q. Which manufacturer would you like to meet on CAPA?

First of all, we want to make a cartridge filter. It is a structure in which a plastic housing is assembled, but it only requires up to 7 molds. Filter production is already being carried out in the water treatment industry, not the bio-industry, but there were many difficulties when we contacted the manufacturer directly. It would be nice to further advance each other’s business with a partner with a spirit of challenge who wants to build an automated process.

Q. Do you have anything more to talk about?

UMTR’s products are a policy-indispensable business for the bio-industry and Korea. It isn’t easy, but UMTR is doing it.

The source for this article is a Korean piece located at CAPA website. This version has been translated into English with additional revisions for clarity.