The manufacturing sector across the globe is looking towards alternate eco-friendly ways to process operations and manage systems. Korean startup Jushin Global Tech Co., Ltd. is a company that manufactures and sells gas-saving injection molding, an eco-friendly approach for making plastic.

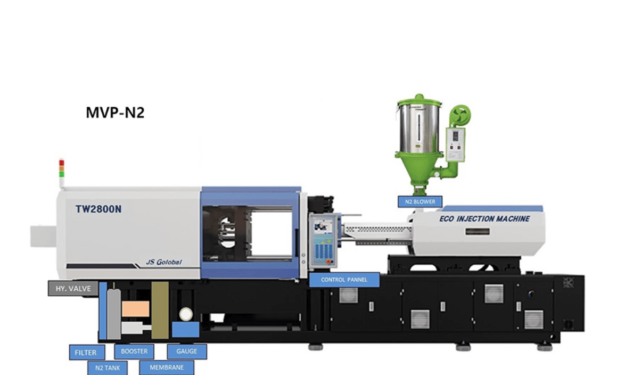

The manufacturing startup has developed a Nitrogen pressure Vacuum injection molding machine that saves the company’s gas and conserves the environment. The eco-friendly injection molding machine can utilize 100% of waste plastics, increasing the recycling rate of waste plastics.

Nitrogen pressure Vacuum injection molding machine

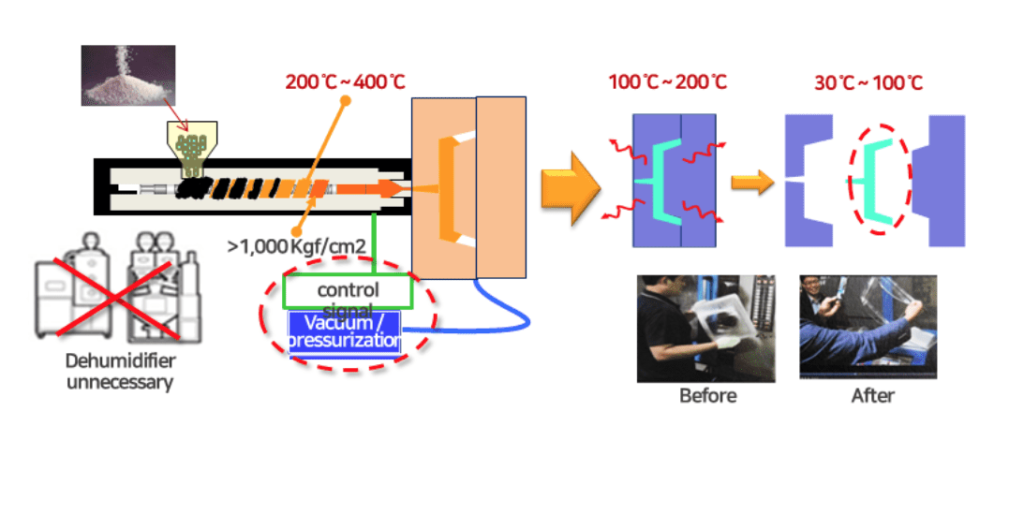

Injection molding is mainly used in the manufacturing industry for fabricating plastic parts. The injection molding process produces various products that vary in complexity, application, and size. The process requires the use of an injection molding machine, a mold and raw plastic material. The plastic is melted in the injection molding machine, then injected into the mold, where it cools and solidifies into the final part. The problem with the traditional plastic injection molding process is that it’s hard to maintain pressure through the material feed rate and resin’s freeze before fully forming the plastic.

Jushin Tech CEO Kil Nam Jang explained, “The problem with conventional injection molding is the freeze off occurring during cooling. As soon as that part cavity is filled, freeze off begins. It starts from the mold cavity walls and works its way back to the center, to the thickest areas of the part. You can only maintain pressure on that part by forcing more material into it until the actual gates freeze off. Then you won’t be able to apply pressure to the part any longer.”

Jushin Global Tech’s pioneer product, the Nitrogen pressure Vacuum injection molding machine, solves these problems. It is a system that solves the problem of eliminating environmental pollution by developing eco-friendly injection molding device technology that can utilize 100% of waste plastics, increasing the recycling rate of waste plastics. The new eco-friendly machine pumps nitrogen gas to the molding process, eliminating quality issues associated with conventional injection molding. The nitrogen gas pushes the resin to the end of the mold such that it starts solidifying as soon as it hits the wall.

The injection molding machine minimizes 100% of waste plastics by first pumping a pre-selected amount of resin into the mold, followed by nitrogen and finally a void in the middle part. The void created between nitrogen and resin eliminates a tremendous amount of resin waste with the evenly applied gas pressure minimizes warpage and shrinkage of the plastic during cooling. Thus, the machine minimizes the mass cooling at the end of the process and the cycle time, allowing firms to produce a wide range of plastic designs faster and with less material.

Features of the product

- Vacuum mold by sealing the mold core pins and cavity external angles.

- After removing the residual harmful gas from ‘the cavity’ with a vacuum pump, apply a pressure of 5 to 30 bar to the cavity to increase the boiling point of the weld pool to prevent the molten resin’s vaporization.

- The machine enables good cosmetic products without the need for resin drying to solve problems of existing technology

Expansion plans

Since the startup’s inception in February 2018, its investments have increased with the firm securing more than $30000000 funds. The firm has grown into a global small-mighty enterprise with technology that dramatically reduces the cost of injection. The firm’s innovative technology hasn’t gone unnoticed as the firm took part in COMEUP 2020 held in Seoul, Korea, Thailand Intermold Exhibition and Seminar, and won the Hyundai Heavy Industries’ Best Technology Contest Award.

Jushin Global Tech is keen to increase its product portfolio and has partnered with Samjung Engineering Co., Ltd for the Pressurization System’s joint development. With continued support from the government and other shareholders, Jushin Global Tech has a bright future in the manufacturing sector.

Also Read,

- Korean startup Oysterable striving to make the planet cleaner with its smart IoT waste recycling solution

- World Environment Day: Korean startups that are helping live a cleaner & sustainable lifestyle

- Korean startup Komachine revolutionizes the machine industry by taking it online

- Korean startup Innerbottle that produces zero-waste dispensers starts Kickstarter campaign