COVID-19, which began in late 2019, has wreaked havoc in the entire world, with cases continuing to rise every day South Korea, It is one country which had success in controlling the outbreak. Its most advanced medical facilities and the Korea Center for Disease Control & Prevention Center (KCDC) has become an excellent example of a proper diagnostic & quarantine system. Their fantastic supply of Isolation Gowns and other critical PPE has improved the effectiveness of their diagnostic & quarantine system, which other countries do not have the luxury of. But unlike South Korea, some countries are struggling to provide appropriate diagnostic testing for COVID-19 even today.

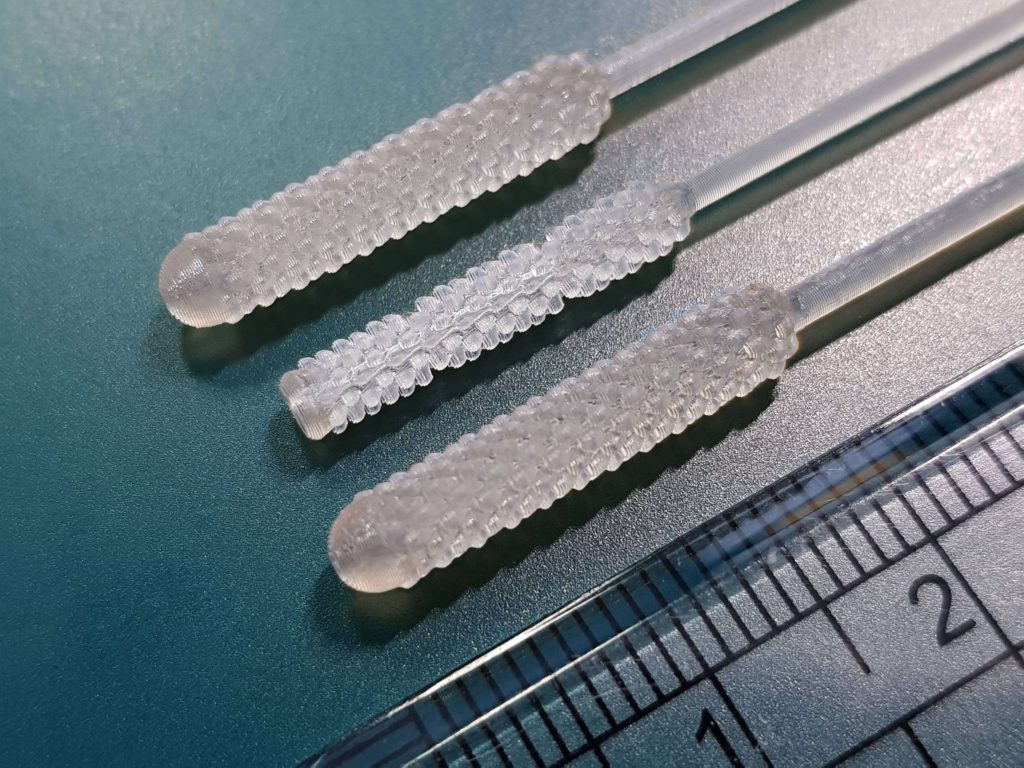

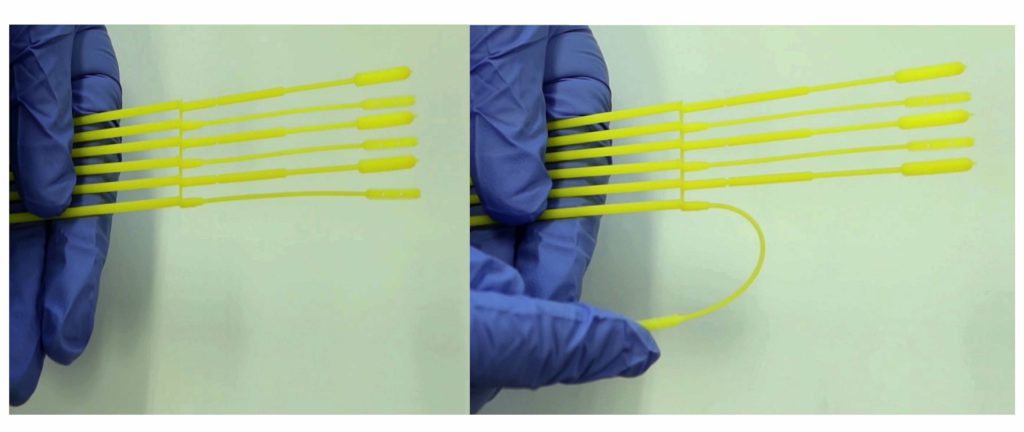

Recently, many Korean manufacturers have exported their diagnostic kits (RT-PCR) worldwide. The United States is one of the most affected countries. Due to difficulty in supplying and shipping in the USA, the USF Health & New York’s Northwell Health team has developed a prototype design for COVID-19 Nasopharyngeal (NP) swab. The 3D printed NP swab design is said to be a more effective way to collect a test sample of the virus. The clinical trial and verification process for the same has been completed, and the manufacturing process using the 3D printer (DLP-SLA) has begun.

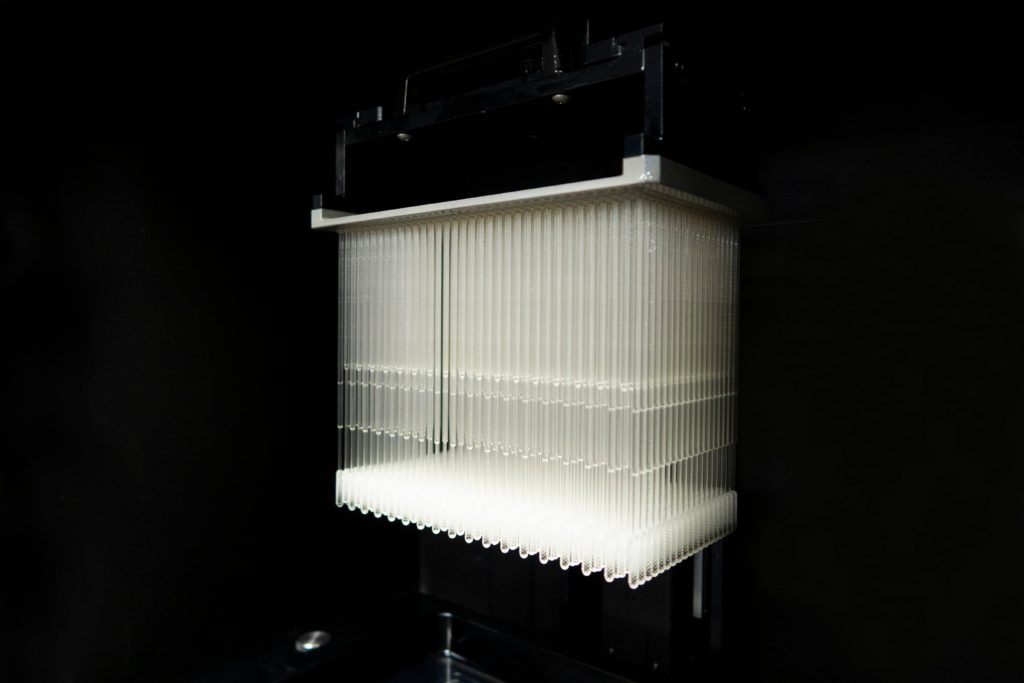

Korean company Carima, a manufacturer of specializing in high-precision 3D printers that can print dozens of micro-structures, actively participates in the production of NP swabs and face shields using 3D printing cope with COVID-19 pandemic.

Carima’s partner company ‘T’ in the USA produces an average of 15,000 NP swabs a day and continues to increase the number to 25,000 NP swabs a day. COVID-19 swab needs to be flexible enough to enter the nasal cavity and strong enough to withstand a considerable amount of mechanical force without fracture or shear. Besides 3D printers, partnering companies are positively considering on using Carima’s newly released nontoxic material.

Nontoxic Face-Shields for health professionals

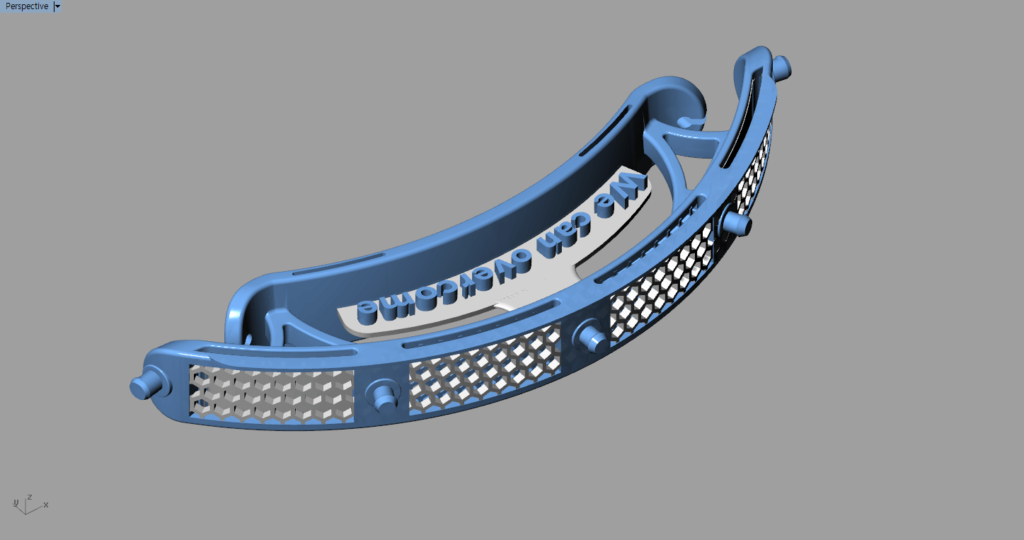

The majority of healthcare professionals across Europe and the United States are having difficulty finding personal protective equipment. Doctors in the United Kingdom have reached a point where they have to manage their own protective equipment. Carima has donated its self-designed face shield to help the healthcare professionals in South Korea. To help healthcare professionals struggling in the front line against COVID-19, Carima has started to supply its self-designed and manufactured face shields to hospitals across South Korea.

Because the face shield’s frames are directly in contact with the skin, it has been printed with nontoxic material. Carima’s face shields are reusable once it is cleaned with soap and allows clear view and prevents fogging. The design was modified multiple times for the wearer’s convenience through user testing.

With the addition of DfAM(Design for Additive Manufacturing), the shield frame weight adds up to only 40 grams. 3D printing has the advantage of allowing immediate output of customized designs, and Carima used this advantage to create seven types of face shield design in one month. Carima’s large-scaled DLP 3D printers can produce around 100 face shields a day.

Carima has produced a large number of the face shields and donated it to four major hospitals for the COVID-19 diagnostic test across South Korea. Also, Carima’s face shield data was made public on its website for 3D printing companies worldwide, encouraging them to provide 3D printing solutions to its community.

Carima also acquired a GMP license (Lv. 2) to produce 3D printing medical devices and continue expanding its 3D printed application in the medical field. The 3D printing industry is expected to continue to take an active part in the future due to the global pandemic having paralyzed global supply chains and demand in certain areas of medical supplies.