As the saying goes, “the beginning is half the battle,” which holds in all aspects of life. The same applies to the creation of products. The initial product produced to check the completeness of the design during the process of realizing an idea is called the ‘starting piece.’ Think of it as a test product made to check if it is implemented as designed before entering the manufacturing process, ensuring no issues such as tolerances exist.

On the other hand, a ‘prototype’ is produced through standardized manufacturing processes to verify the manufacturing quality after the starting piece, taking place in the subsequent stages of the process. It is a stage where the overall process is checked for its completeness, such as the quality of equipment, the skill level of workers, total processing time, etc.

The online manufacturing platform CAPA offers various manufacturing services, including design/engineering, 3D printing, and CNC machining, allowing for the production of starting pieces and prototypes. Especially for those lacking specialized knowledge in manufacturing during the process of turning ideas into products, finding a reliable partner to entrust with starting piece design to production is crucial. CAPA’s one-stop product development service, launched in July, has become a highly popular service, with an average of 30% of monthly quote requests.

Reflecting the importance of the ‘beginning,’ many of CAPA’s customers seem to empathize with this concept. With the growing number of startups, small brands, and solo entrepreneurs, specialized starting piece manufacturing partners are emerging. In this article, we introduce EVM, a starting piece specialist partner founded through youth entrepreneurship, sharing insights from an interview with its CEO, Kyewon Rho.

From Customer to Partner: Symbiosis with CAPA

CEO Kyewon Rho graduated in Automotive Engineering and started his career as a welder. He later worked in the automotive industry, handling advanced development and starting piece-related tasks. In charge of designing products, meeting manufacturing partners to negotiate quotes, and checking the quality of the products he produced, he managed the entire process of starting piece production. During his focused research in the field of electric vehicle design, he earned environmental certification.

At the time, while searching for a manufacturing partner to handle starting piece production, Rho came across CAPA through a search for ‘real-time quotes.’ He highlighted CAPA’s advantage as a manufacturing platform specializing in matching with manufacturing experts, allowing for outsourcing various manufacturing services. Now, as the representative of a manufacturing company, he expressed satisfaction with how CAPA facilitates meeting customers quickly and easily.

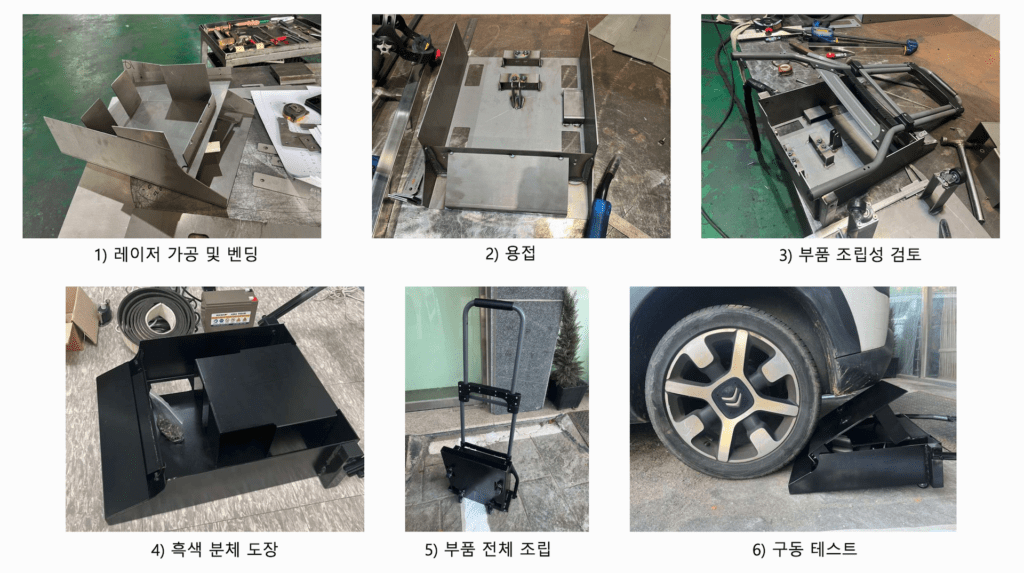

Dedicating to ‘Starting Piece’ Production for Idea Realization With a keen interest in youth entrepreneurship since his 20s, Kyewon Rho worked in the automotive industry for eight years, gaining experience. After accumulating experience, he founded EVM. Leveraging his experience of ordering starting pieces from manufacturing companies as a customer, he now provides a range of manufacturing services, including package design, structural design, bracket design, structural analysis, and manufacturing processes like laser cutting, bending, welding, and CNC machining.

EVM recognizes the challenge of turning ideas into products when one needs help finding the right manufacturing partner, regardless of how good the idea is. Noh states, “For startups in the stage of having only ideas or starting a business on a minimal scale, it’s challenging to make wise decisions during the product development process.” Lack of expertise in the field, shortage of specialized personnel, and limited information about manufacturing companies are common hurdles that people face if they are not part of the industry.

Why is EVM able to provide quotes that are, on average, 3 to 4 times cheaper?

EVM places a strong emphasis on calculating quotes from the customer’s perspective. According to Noh, when manufacturing companies provide quotes for starting pieces, the current situation of the production line influences the quote, resulting in market prices that are on average 3 to 4 times higher than mass production prices. Customers may leave for companies that offer more reasonable prices or face difficulties proceeding with mass production due to the manufacturing schedule needing to align with theirs.

EVM currently operates research facilities in Gunpo, Gyeonggi-do, and carries out production in laser, bending, welding, and CNC machining factories in Siheung and Bucheon. These factories are long-standing partners that Rho has built a strong trust with since before starting his own business. From the perspective of manufacturing plants needing more design expertise, it is easier to respond to beginning piece requests from customers with proper drawings. Therefore, there was no reason for Rho to refuse cooperation with his design skills.

Leveraging its network with these partners, EVM can produce starting pieces at a cost comparable to mass production prices. This is achieved by focusing on the production site and presenting optimal design plans from the customer’s perspective. To maintain a systematic and strong cooperative relationship, Noh holds production schedule meetings at the beginning of each month. Especially for starting pieces, where the possibility of transitioning to mass production is high, customers can start without going through multiple manufacturing companies, ensuring a stable start.

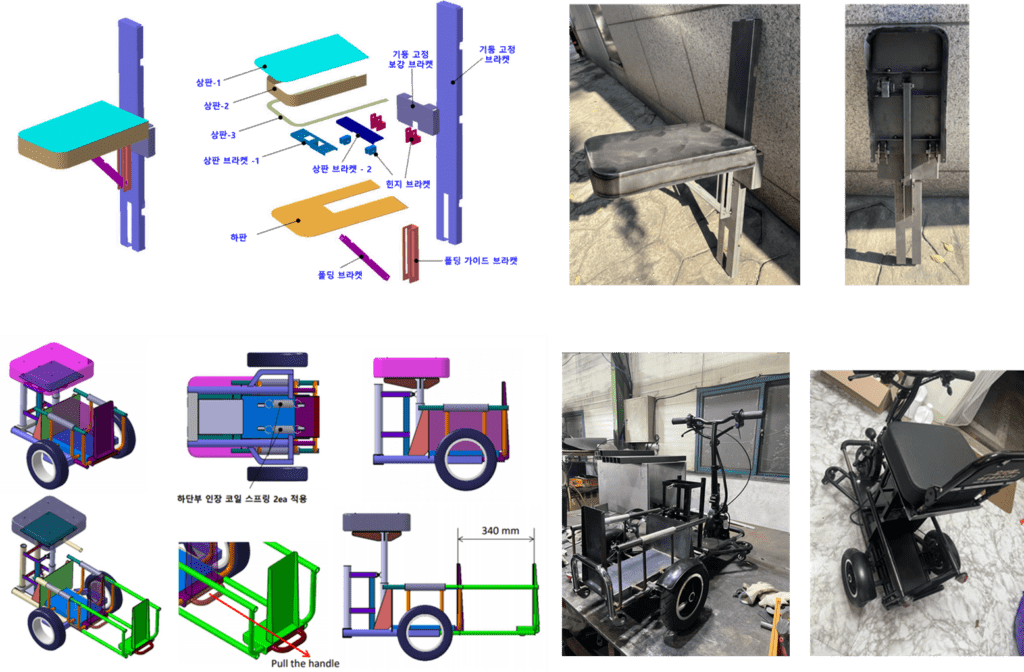

Portable bollard production process (Photo: EVM)

Even Night Shifts on Weekends and Holidays are “Worthwhile”

Despite being a newly established manufacturing company just two months into its startup, Rho, the CEO of EVM, is already busy with orders through CAPA. He works tirelessly, returning on weekends and even during the Chuseok holiday, to dedicate himself to customers’ projects. Despite the exertion, he expresses excellent satisfaction every time he receives feedback from customers who are satisfied with the products EVM has manufactured.

The project that CEO Kyewon Rho considers most memorable is the ‘portable bollard’ commissioned by a police station. The portable bollard is a product that, when placed on the wheel of a vehicle and remotely lifted, prevents a fleeing vehicle by raising its plate aiding police investigations. EVM, considering the need for more knowledge about drawing design on the part of the police station, designed the drawings themselves, produced the product, and personally visited the manufactured product for a demonstration. It was reported that the police station participated in the ‘2023 National Safety Invention Challenge’ with this product.

EVM plans to establish a one-stop service responsible for all processes in the future, from starting pieces to mass-produced items. Currently focusing on mold-related research, Kyewon Rho plans to provide mold manufacturing/injection services through EVM, stating, “EVM will develop providing mold and injection services by dedicating itself to research and studies.” CAPA will continue to respond to the trust of its customers by providing even better services, enabling EVM to take responsibility for more starting pieces of customers.

Also Read,

- UMTR Teams up with CAPA to Pioneer Localization of Biomembranes & Shape the Future of the Bio-Industry

- ZEEZIK Addresses LP Infrastructure Gap with Partnership with CAPA and Attracts MZ Generation

- Online Manufacturing Platform CAPA Partners Thrive at NextRise 2023, Showcasing the Future of Manufacturing

- Fuelling the Future: Young Korean innovators propel Rocket manufacturing with online support from CAPA

Keep tab on latest news in the Korean startup ecosystem & follow us on LinkedIN, Facebook, and Twitter for more exciting updates and insights.