When it comes to sealing a deal between customers and manufacturing partners, one might argue that ‘trust’ is the most crucial element. In the realm of online manufacturing outsourcing, CAPA platform provides various features allowing customers and partners (manufacturers) to build mutual trust even without direct interaction. Notable among these features are chat and drawing viewer functions, along with the recently updated ‘Safety Number’ service.

The common thread among these features is ‘communication.’ CAPA believes that trust between customers and partners originates from effective communication. As transactions take place online without face-to-face interactions, building trust without communication becomes challenging. Particularly from the partner’s perspective, communication with the customer is deemed essential for securing new deals, especially when presenting competitive price quotes.

This article highlights iContact, a 3D printing partner located in Ulsan, as an exemplary partner excelling in communication on the CAPA platform. We interviewed the founder and CEO of iContact, An Hyeongchan, who, at the age of 29, operates a thriving 3D printing company. CAPA delves details behind his active deal acquisition and his strategies for successful communication with customers.

Evolving 3D Printing with a Focus on Cost Reduction

iContact, situated in the Ulsan 3D Printing Venture Knowledge Industry Center, positions itself as a 3D printing manufacturer committed to successfully integrating 3D printing into the manufacturing industry. An, the CEO, decided to venture into 3D printing after receiving inquiries from industry peers during his tenure at a 3D printing manufacturing company while completing the top executive program at Ulsan University.

3D printing involves several manual steps, from moving and cleaning the printed product to removing support structures and finishing touches. Although 3D printing technology itself is innovative, the associated processes are labor-intensive, leading to higher market prices and challenges in mass production. An recognizes that in order for 3D printing to be recognized as an innovative technology in manufacturing, ‘price competitiveness’ and ‘mass production’ are key.

An emphasizes that the 3D printers used by most domestic 3D printing manufacturers have similar performance levels, making the quality difference negligible. Hence, to achieve price competitiveness and enable mass production, iContact focused on building an ‘automation system.’ This strategic move allows iContact to offer services at a more affordable price compared to other manufacturing companies.

iContact has patented its automated washing system, a crucial component in reducing costs. An has completed the patent registration and aims to fully automate all production processes within the next five years. The resources saved through automation will be reinvested in research to enhance technological capabilities and further improve the quality of output.

Trade Secrets for Winning Deals: “Communication 24/7”

Since joining CAPA as a partner just four months ago, iContact has already secured more than ten deals, a remarkable growth trajectory in the fiercely competitive 3D printing sector. An attributes much of this success to conducting specific and detailed consultations with customers using the various features provided by CAPA.

An states, “I respond to inquiries 24/7, excluding sleep hours,” emphasizing the significance of continuous communication with customers. He receives notifications for all types of CAPA alerts, including quote requests, project updates, chat notifications, and CAPA news and benefits. He is active on both KakaoTalk and email, using his smartphone primarily for real-time notifications and his laptop for reviewing drawings or thoroughly examining detailed customer requests.

Recognizing that customers appreciate prompt responses, An ensures to reply to all inquiries within an average of one hour. This dedication has resulted in significant returns for iContact, with one customer starting with three items and eventually placing an additional order for sixty items. An underscores the advantage of investing time in consultation, even with just one customer, as it can lead to repeated transactions and customer loyalty.

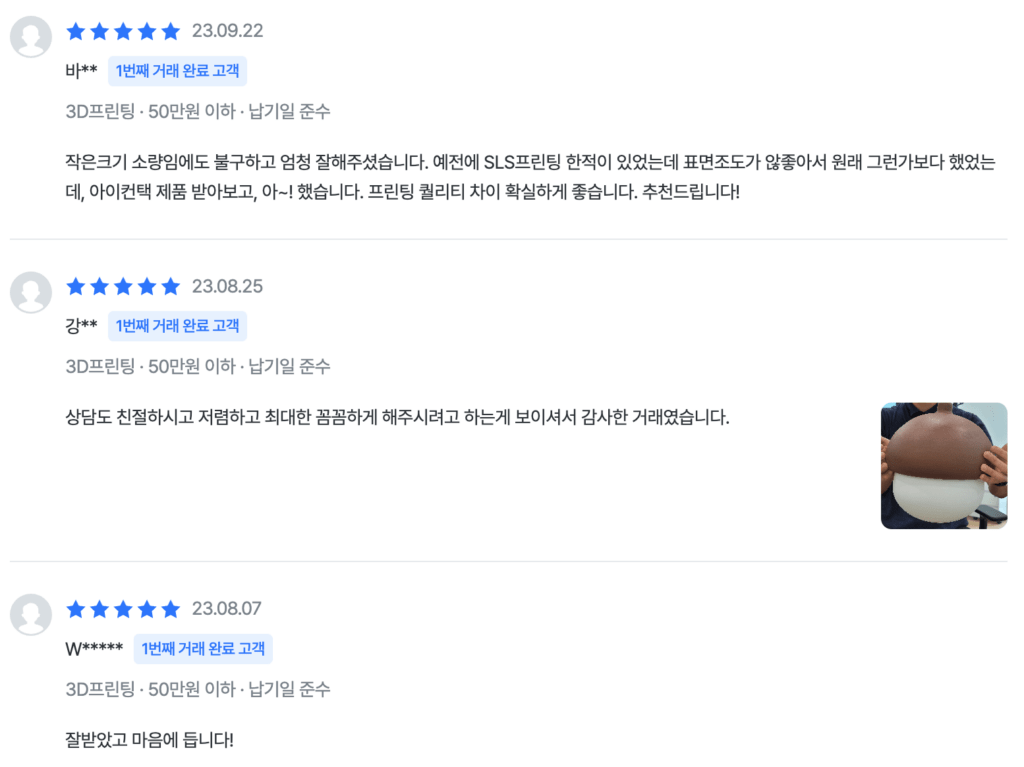

Customer Reviews Reflecting Genuine Communication Efforts

iContact’s profile on CAPA is adorned with ‘5-star’ reviews from satisfied customers. An vividly recalls a customer who engaged in detailed consultations over several days, involving multiple revisions before final delivery. The customer, impressed by An’s efforts, left a review stating, “The consultation was friendly, the price was reasonable, and it was evident that he tried to be as meticulous as possible. It was a transaction for which I am grateful.”

Even recently, iContact successfully secured an order by promptly accommodating customer-requested quote revisions within ten minutes. The synergy between manufacturing expertise and swift responsiveness culminated in a successful deal for Aicontact. An concludes by expressing his gratitude to CAPA customers and delivers a message: “I respond to everything with dedication. Please feel free to contact me for any inquiries or consultations.”

In conclusion, iContact’s story on the CAPA platform serves as an inspiring example of how genuine and continuous communication can lead to building trust, securing deals, and fostering customer satisfaction in the competitive landscape of online manufacturing.

Also Read,

- EVM: Empowering Innovation from Ideas to Prototypes with CAPA Partnership

- UMTR Teams up with CAPA to Pioneer Localization of Biomembranes & Shape the Future of the Bio-Industry

- ZEEZIK Addresses LP Infrastructure Gap with Partnership with CAPA and Attracts MZ Generation

- Online Manufacturing Platform CAPA Partners Thrive at NextRise 2023, Showcasing the Future of Manufacturing

- Fuelling the Future: Young Korean innovators propel Rocket manufacturing with online support from CAPA

Keep tab on latest news in the Korean startup ecosystem & follow us on LinkedIN, Facebook, and Twitter for more exciting updates and insights.